Background image operating advice Help and Advice

Zoom sur les roues d'un camion équipé en pneus Michelin

Operating advice

INTRODUCTION TO FITTING TRUCK AND BUS TYRES

Before commencing the tyre fitting process the conformity and compatibility of the tyre with the wheel and the vehicle must be established.

Correct tyre fitting carried out with the recommended methods of work and in line with the safety rules in force, helps to ensure that the tyre will be used to its full potential.

A. General precautions

- The operators must always be equipped with their usual protective clothing (ear defenders, gloves, safety shoes, etc.).

- The operators must be correctly trained for the work they are carrying out and use appropriate equipment.

- The vehicle must be stationary with its engine switched off and must be correctly stabilised (parking brake, chock, axle stands, etc.).

B. Fitting precautions

Make sure that the wheel and its components are suitable, clean and in good condition.

- Check the compatibility of tyre and wheel, tyre and vehicle and tyre and use.

- Respect the positions, fitting direction, direction of rotation and any relevant instructions when mentioned on the tyre sidewalls.

- Make sure that the inside of the tyre is clean, dry and free of foreign matter. For a tyre which has already been used on the road, check carefully that the inside of the tyre does not show any signs of having run under-inflated (mottling, dislocation).

- Change the valve seal for tubeless wheels or the tube and flap for tube type wheels.

- Make sure that the tyre is centred on the rim during the inflation operation.

- Inflate the tyre safely to the manufacturer’s suggested operating pressure. Make sure that all of the components are correctly in place. Never stand facing a fitted tyre. Stand in line with the tread, at least 3 metres away. Always use an inflation cage where possible.

- All of these precautions must be used for both new tyres and tyres that have already been used on the road.

- We recommend fitting tyres on wheels with protected valves for vehicles equipped with disc brakes to prevent the risk of the valve being damaged by an object jammed between the brake and the wheel.

- Incorrect tyre and wheel fitting may lead to damage to tyres and vehicles and injury to persons (serious or even fatal injury).

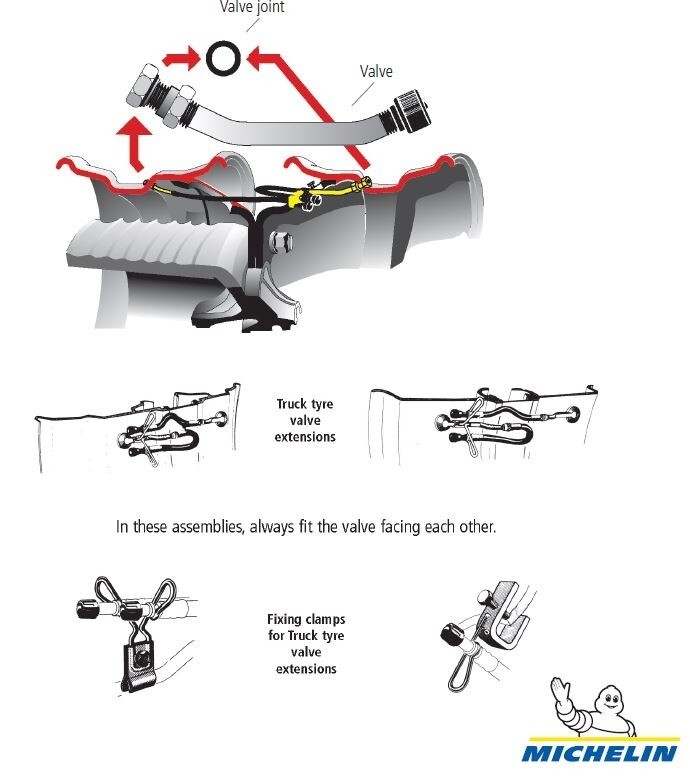

C. Verification of valves

Because of ageing and the high temperature linked to brakes, valve seals and inflation extensions are to be replaced each time a tyre is changed.

A valve cap in excellent condition is essential for maintaining an air-tight seal.

Picto maintenance page 27 Help and Advice

Sealing diagram for twin fitment. For this type of fitment, always position the valves facing each other.

BEST PRACTICE FOR TYRE INFLATION

Inflation pressure in workshop

This must be carried out by competent personnel using the correct equipment. Incorrect fitting can result in damage to the tyre (may not be visible at the time of fitting), tube or wheel.

Cold tyre pressure must be determined based on load, speed and conditions of use.

Michelin recommends inflating tyres using a safety cage.

You should inflate tyres in two stages:

1st Stage:

• pre-inflate to 1.5 bar (21.7 psi)

• general inspection of the tyre

2nd Stage:

• inflate the tyre to the required pressure

• during inflation, the tyre must be placed vertically in an inflation cage, or a suitable secure area.

The operator must position himself in line with the tread band during inflation.

At all times whilst inflating, stand at least 3 metres from the fitted assembly in line with the tread band.

Edito la juste pression photo principale Help and Advice

Stand in line with the tread band and at least 3 metres away during inflation.

BALANCING

It is important to make sure tyres are correctly balanced, as this:

• helps tyres to achieve maximum mileage performance

• protects mechanical parts from premature wear

• ensures a comfortable ride

If balancing is required, Michelin recommends dynamic balancing using weights applied to the wheel.

WHEEL INSTALLATION ON VEHICLE

After fitting the wheel on the vehicle, the wheel nuts must be tightened with a calibrated torque device to the torque setting defined by the vehicle manufacturer. The correct wheel tightening process is essential to maintain wheel security, and along with it your safety.

A. Wheels condition:

- The condition of wheels must be checked regularly. A cracked wheel or rim must be replaced.

- Wheels and rims must not be repaired by welding.

- If a welding operation has to be undertaken, the tyre must be removed from the rim. If this is not done, there is a serious risk of explosion.

- The tyre can be refitted when all elements have returned to ambient temperature.

- Before any welding on the vehicle chassis, the tyre and wheel assemblies should be removed from the vehicle.

- Before removing divided wheel assemblies from a vehicle, it is recommended that the tyres are deflated.

B. Before mounting / wheel assembly, the following must be observed:

1. Clean:

- the support surfaces of the hub and wheel.

- the wheel studs and nuts.

2. Check:

- the condition of the fixing holes (deformation, cracks, etc.).

- the condition of the studs (deformation, state of threads, etc.).

- the condition of the nuts (deformation, state of threads, etc.).

- corrosion and any paint, removing with a wire brush if necessary

- any burrs, loose or flaky surfaces, on the metal

3. Lubricate:

- the threads of the wheel nuts with a drop of oil

- never lubricate the mating face of nuts or washers

4. Final tightening torque:

- Use a calibrated torque device.

- Follow the methods recommended by the vehicle manufacturer and their recommended tightening torques.

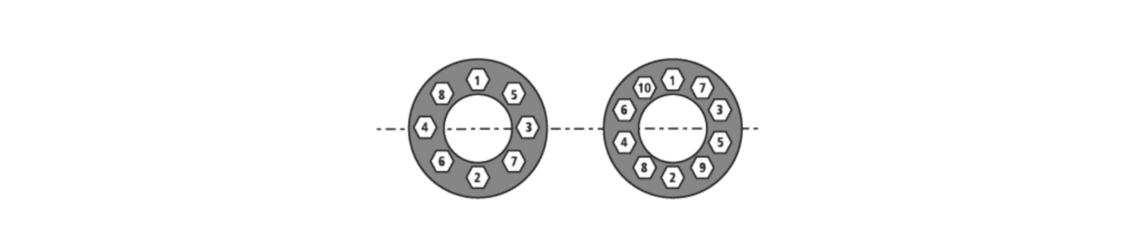

- The nuts should be tightened alternately diagonally according to the number of nuts as per the illustration below. The diametrically opposite rotational sequence ensures that the mating faces are pulled together squarely and evenly.

- Tightening to the correct torque with a calibrated torque device makes the wheel easier to remove in the event of a puncture, does not distort the studs and helps to ensure safe operation.

Over-tightening is often just as harmful as not tightening enough and can result in:

- deformation and/or cracking of wheel studs,

- distortion of wheel nut threads which may even lead to wheels loosening,

- ovalisation of drums, etc.

After a period of thirty minutes, or after 50 – 100 kilometres of use, the wheel nuts should be rechecked for tightness using a calibrated torque device. When the retorque is carried out, the nuts should not be slackened off and then retightened. They should simply be checked.

Picto Schema maintenance clamp Help and Advice

CARE AND MAINTENANCE

Tyres must be examined regularly. Make sure the vehicle is stationary, the engine is switched off and it is completely immobilised before any inspection.

A. Tyre care

Tyres must be examined regularly. When doing this, make sure that the vehicle is stationary, the engine is switched off and it is completely immobilised before any inspection.

B. Care of tyre

- Tyres on a vehicle must be checked regularly, taking particular care to check:

- the tread, for signs of abnormal wear, cuts, deformations and embedded foreign objects (stones, bolts, nails etc.),

- the sidewalls for cuts, impact damage (caused by pot-holes, riding kerbs, etc.), rasping due to kerbing, and abnormal deformations.

- Causes of vehicle handling problems such as steering wheel vibrations, pulling to left or right, etc. should also be investigated.

- If loss of pressure occurs, it is imperative to stop as quickly as possible, as running underinflated causes thermal degradation of the tyre components.

- The tyre should be removed from the rim, and the reason for the loss of pressure determined.

- Any damage must be examined by a tyre professional who is capable of determining if a repair is necessary or possible.

- Repairs must be undertaken by a tyre specialist, who will accept responsibility for the repair.

- Before any repair, the interior of the tyre must be examined to ensure that no degradation has occurred.

C. Tyre inspection and recommendations

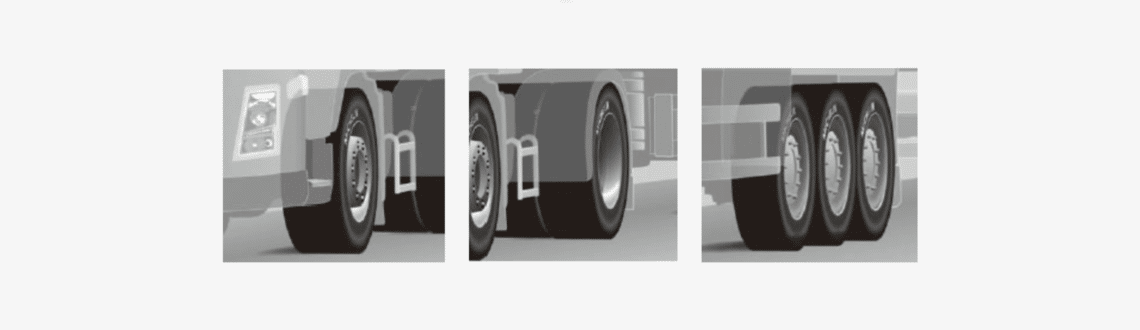

Picto truck axles Help and Advice

Axles, from left to right: Steering (F), Drive (D), Trailer (T)

1. Tyre wear on the STEERING AXLE of motor vehicles

Observations

- The front nearside tyre normally wears more quickly than the front offside tyre on a truck driving on the left.

- The front nearside tyre often has more pronounced wear on the outer fitted shoulder due to the camber of the road and the number of roundabouts.

Our solutions:

To even out front tyre wear if necessary turn tyres on the rim when half worn and interchange left to right. Regroove at the appropriate time. Michelin advises against fitting retreaded tyres on the front steer axles of motor vehicles.

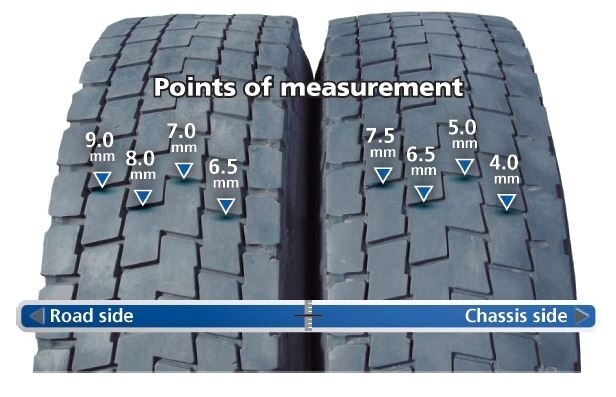

2. Tyre wear on the DRIVE AXLE

Observations

- As a general rule, both the inner tyres have more pronounced wear on the tread shoulder, on the inner side of the chassis.

- Several factors are involved: camber angle, type of suspension, use of the engine brake, the route conditions and the axle load.

Our solutions:

To even out wear and take advantage of the full potential of the four tyres by integrating regrooving, follow the advice below:

- Switch the inner and outer tyres round (twin fitment)

- Turn the two inner tyres on their rims whilst observing direction of rotation

- Regroove with 3 to 4 mm of tread remaining

Fit retreaded tyres on drive axles in rear position.

3. Tyre wear on CARRIER AXLE (case of semi-trailers with 3 fixed axles)

Observations

As a result of lateral scrubbing whilst cornering and maneuvering, the wear rate of the tyres fitted on the 3 axles is not uniform:

- The 1st axle is moderately affected by scrubbing and will therefore have a level of wear mid-way between that of the 2nd and 3rd axles.

- The 2nd axle, with virtually no stresses, has a very low degree of wear.

- The 3rd axle has more rapid wear because it is most affected by scrubbing linked to the geometry of the vehicle.

Our solutions:

To even out wear and take advantage of the full potential of both tyres by integrating regrooving, follow the advice below:

Tyre rotation:

- Turn the tyres on their rims on the 1st and 3rd axles when approximately 50% worn.

- Regroove (at 3 - 4mm remaining tread pattern depth):

- On 1st axle use of regrooved tyres is possible depending on use.

- On 2nd axle use of regrooved tyres is usually recommended.

- On 3rd axle use of regrooved tyres is not normally recommended.

3rd axle tyres may be regrooved and fitted to the 2nd axle.

For trailers and semi-trailers, MICHELIN Remix tyres can be fitted in any position.

D. Tyre rotation and turning on the rim

What is it?

Tyre rotation is an operation consisting of removing the tyre from one position on the vehicle and refitting it in another position.

Turning on the rim is an operation consisting of removing the tyre from the rim and refitting it the other way round.

These two operations can increase tyre longevity by about 20%*.

Example: wear on the drive axle tyres

Some truck tyres have a direction of rotation which should be complied with at the start of the tyre’s life to optimise all round performance. In this case, when rotating tyres, it may be necessary to also turn on their rims to maintain the recommended direction of rotation.

Edito maintenance page 34 Help and Advice

E. Wheel alignement

By measuring and adjusting wheel angles on a vehicle, fuel costs and tyre wear are reduced.

This leads to better economy and environment for everyone. It also means improving safety in taking up less space with a vehicle traveling on highway with correctly aligned wheels.

PRECAUTIONS FOR REMOVING TYRES

When removing a wheel from a vehicle,

if the tyre is part of a dual fitment or if the rim shows obvious damage, the tyres:

- must be deflated by removing the valve core before the fitted unit is removed from the vehicle

- Comply the vehicle manufacturer's recommendations and instructions

Removing the tyre with the wheel still fitted to the vehicle

Michelin does not recommend this practice which should only be used if it is not possible to remove the wheel. If this case, deflate the tyre entirely by removing the valve core.

STORAGE AND HANDLING

A. Conditions for a good tyre storage

- Clean, dry, temperate and well-ventilated premises, sheltered from direct sunlight and bad weather.

- Storage rooms should not contain any equipment generating ozone such as fluorescent lighting, mercury vapour lamps, electrical machines or other equipment which may produce sparks or other electrical discharges.

- Well away from any chemical substance, solvent or hydrocarbon likely to alter the nature of the rubber.

- Well away from any object which might penetrate the tyre (metal spike, wood, etc.).

- Products should be stored in a relaxed condition free from tension, compression or other deformation since these may cause cracking or permanent distortion.

- Rotation of stocks: to avoid deterioration, storage time must be minimised. Stocks should be issued from the stores in rotation so that those remaining in storage are of the latest manufacture or delivery.

• Storage:

– For short term storage (up to 4 weeks) tyres can be stacked horizontally, one on top of another, on wooden pallets but the height of the stacks should not exceed 1.2 metres. After 4 weeks, the tyres should be re-stacked, reversing the order of the tyres. When fitted on rims, tyres should be stored inflated in an upright position or in a single layer on shelf racks.

– For long term storage, tyres should be stored upright in a single layer on shelf racks with at least 10cm clearance above the floor. To avoid deformation, it is advisable to rotate them once a month.

• Tubes:

– Tyre inner tubes should either be slightly inflated, dusted with talcum and placed in the tyres or stored in a deflated condition in small stacks max. 50cm – in the compartments of shelf racks with a level bottom. Slatted pallets are not suitable since they might apply pressure at particular points.

– If tubes are supplied by the manufacturer in cartons or wrapped in film, they should be left in these because the packing provides some degree of protection against contamination, oxygen and the effects of light.

• Flaps:

– Flaps should preferably be placed with the tubes inside tyres, but if stored separately, they should be laid flat on shelves free from contamination, dust, grease and moisture. Never suspend them – this can cause deformation and elongation.

B. When handling tyres and accessories, operators must:

• Follow the company's safety instructions.

• Be equipped with their usual protective equipment for handling.

• Use instruments and equipment that will not damage the tyres.

C. Additional Michelin storage information:

- Stored tyres which reach five years of age, should be examined by competent personnel to determine their suitability for further service.

- It is strongly recommended that fitted tyres which are to be stored should be inflated with Nitrogen. If air is used then it must be as dry as possible before it enters the tyre. Ensure that a valve cap is fitted to the valve.

- Tyres on vehicles resting on the ground should be at the normal pressure for the vehicle.

- Every six months, that pressure should be checked and corrected as necessary. Every four months, the tyres should be rotated ¼ turn. The tyres should be driven for a distance every year until any “flat spotting“ disappears.

- Tyres on vehicles suspended off the ground should be deflated to approximately half the normal pressure for the vehicle.

- Spare tyres in storage should also be deflated to approximately half the normal pressure for the vehicle.

- A procedure must be established to ensure that tyres which have been in storage at reduced pressure, are correctly re-inflated when they are returned to service.

- Any tyre which has been stored, should be visually inspected by competent personnel before entering or re-entering service.

These help and advice pages might also interest you:

• Tyre marking and basics

• Tyre construction and functions

• The right pressure